HomeRobotic Database - Single Infrastructure | TERRINet

Address: Plateau de Saclay, Boulevard Thomas Gobert, 91120 Palaiseau, France

Website

http://www-centre-saclay.cea.fr/fr

Scientific Responsible

Christophe Leroux

About

The aim of the Interactive Robotics Lab (LRI) is to design and develop ICT and robotics solutions to provide support and assistance to citizens in daily life activities. Particularly the studies carried out in the “Active and Assisted Living” field aims to integrate robotics, internet, cloud, mobile and electronic technologies for applications, such as healthcare, agriculture, logistic and manufacture. The main scientific challenges to enhance the abilities and capabilities of robotic systems revolve around the physical and cognitive human robot interaction, the integration in intelligent environments and the dependable design. LRI institute is responsible for the development, integration and transfer of robotics technologies to industry.

LRI is tightly involved in CEA’s Advanced Manufacturing research programme. Specialized originally in remote handling for operations in hazardous environments (nuclear, underwater applications), the LRI has now a large part of its activities devoted to manufacturing in that respect the robotics lab is deeply involved in innovation of the European industry.

The laboratory has an historical background in robotics for Healthcare applications including assistive, surgical robotics and rehabilitation robotics. One part of the laboratory’s activities dedicates to field robotics essentially for agricultural applications. Its main research foci carry on human robot collaboration (co-working). The technological researches cover mechatronics and the conception of actuators for the design of innovative robotics systems, robot control, supervision and user assistances (force, haptic, vision, graphic, immersive feedback) aiming at an efficient human robots collaboration in all domains of applications.

Presentation of platforms

Available platforms

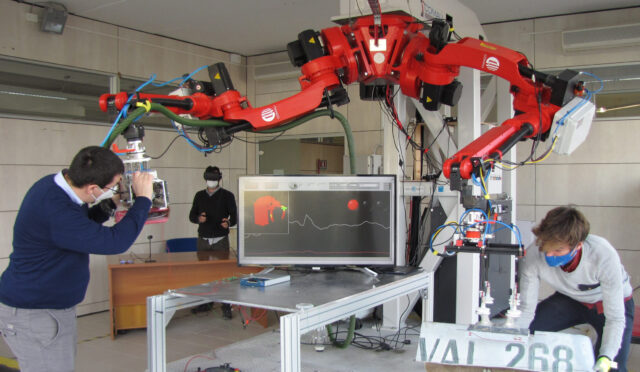

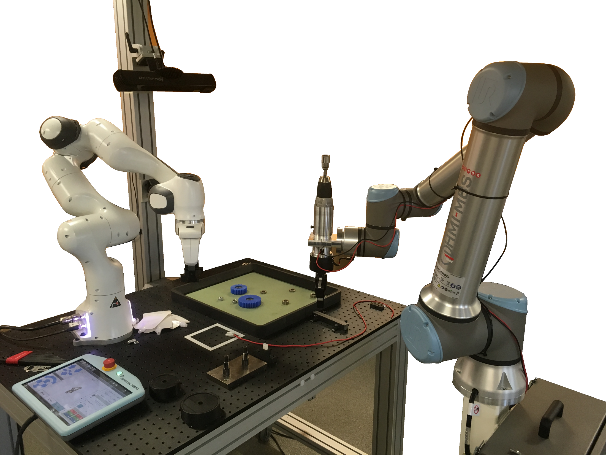

Robot Companion

The Robot Companion is a demonstrator of intelligent interactive robotics focusing on industrial assembly tasks (for example the assembly of a representative gear unit). The system is composed of two collaborative robots, custom end-effectors, vision sensors, and a digital twin of the whole platform. In nominal mode, the robots work autonomously and assemble the different parts using dedicated skills. An interactive mode is also available, allowing a human operator to collaborate with the robots. An environment camera allows monitoring the operator’s actions and adapt accordingly.

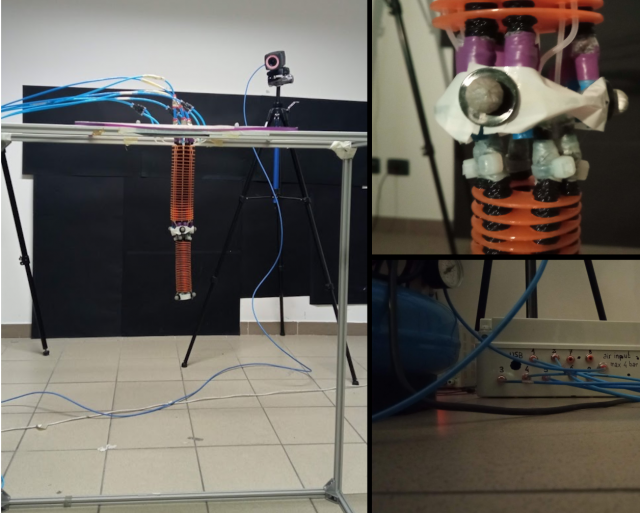

Cobomanip

The Cobomanip assists the operator during handling operation. It is designed as a standard a force generator more than a robot driven in position control mode. In the entire workspace it will assist or oppose to the movements of the operator according to the task definition and the requested assistances. One may therefore consider two distinct operating modes:

-

Movements in free space: the Cobomanip is a perfect balance with 3 or 4 dofs. It behaves like if the load is handled in a zero-gravity area.

-

Constrained movements: motors (one for each dof) apply counteracting torques to limit the manipulator movements into specific directions.

-

All the frictions are compensated with motors situated in the frame of the cobot.

COBOMANIP provides assistances to keep the attention of the operator focused on the main task using virtual guides to constrain the movement within a specific part of the workspace. Concepts for such constraints applied to teleoperation tasks are proposed in two distinct types:

-

The operator cannot enter a specific area of the workspace. The movement is possible until a boundary is reached.

-

Assistance to guide the operator. Movements of the operator are limited to those allowed by a mechanism attached to the robot.

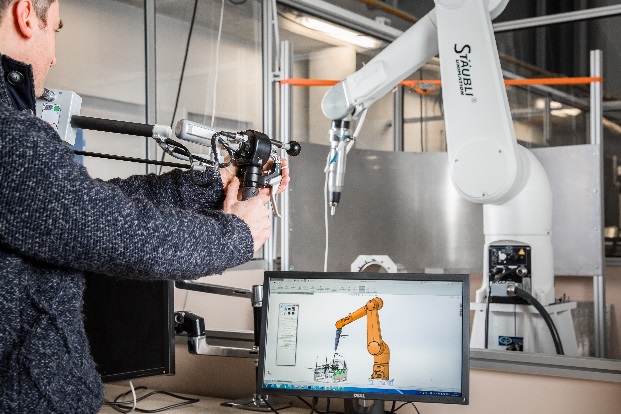

Isybot Syb 3

Thanks to its unique mechanical qualities, the SYBOT brings competitiveness and attractiveness to manual operations that cannot be automated.

Through agile automation, SYBOT simplifies the response to flexibility and variability requirements for all types of processes such as grinding.

Without special training, the operator integrates and optimizes the use of the COBOT by enhancing his know-how in a work environment that does not require any modification.

SYBOT interactive COBOTs improve productivity while reducing operator fatigue.

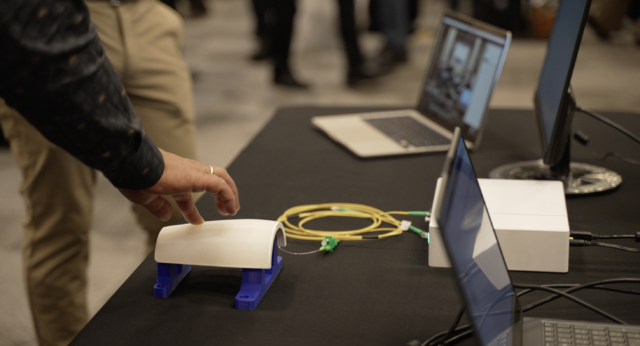

Haption Virtuose 6D

The Virtuose 6D is the only product on the market combining a high force feedback in the 6 degrees of freedom with a large workspace. The Virtuose 6D is especially suited for scale one manipulations virtual and distant (robotic control). It is also used as a co-manipulation medical robot and in rehabilitation applications. Its handle has 3 buttons (2 programmable), and is replaceable through our tool changer. You can for instance use it with 3D printed objects. This product is available in a High Force Version, for applications in need of a very high level of force feedback.

TX90 6-axis robot

The TX90 6-axis robot is an articulated arm with 6 axes for increased flexibility. The spherical work envelope allows maximum utilization of cell workspace. It can also be mounted on the floor, wall or ceiling. The fully enclosed structure (IP65) makes the robotic arm ideal for applications in harsh environments. The TX90 6-axis robot has a maximum payload of 20 kg and a 1000 mm reach.

Haption ABLE

The Able is an exoskeleton haptic interface for the arm and the hand. It provides from 4 to 7 active degrees of freedom. Able is the first industrialized exoskeleton haptic device – it can be ordered off-the-shelf. The Able is available for right configuration and for left configuration.

Kinova Gen3

Extremely versatile and portable, the KINOVA Gen3 Ultra lightweight robot is built for human-robot interaction. Which means it’s not intended to automate tasks, but rather to work with people, enabling you to transcend your physical limitations with confidence. The new interface allows simple connectivity with a wide variety of end effectors, instruments and sensors, and the practical controller makes the robot adaptable for multiple application needs.

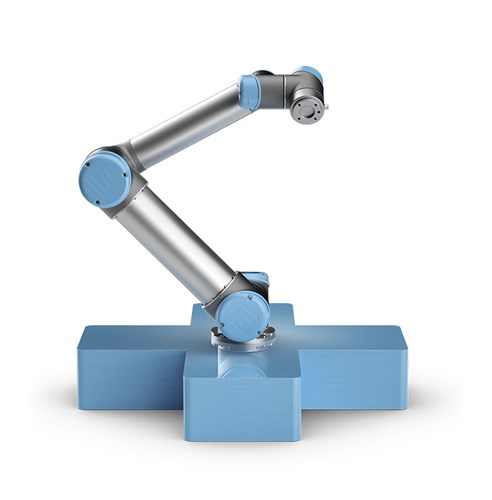

UR10 Universal Robot

Collaborative robot UR10 are designed to mimic the range of motion of a human arm and incidentally all it takes to program and reprogram the robotic arms is a human arm. It doesn’t get any easier – and perhaps most importantly it eliminates the need for expensive third-party programmers every time you want to assign the robot arm to a different task. The intuitive software allows even the most inexperienced user to quickly grasp the basics of programming and set waypoints by simply moving the robot into position. Recurring tasks, programs can be stored in the UR robot arm and re-used. FAST SET-UP, EASY PROGRAMMING, COLLABORATIVE AND SAFE, FLEXIBLE DEPLOYMENT