Marek Vagas is an associate professor at Technical University of Kosice, Slovakia. He currently focus on collaborative robots programming (from various manufacturers), and applied to the TERRINet project to study, testing and verifying mechanical and programming aspects of dual robotic system with focus to level arm motions as well as bi-manual actions to obtain higher degree of such workplaces designing, its operation and increasing of education quality for teachers, students and SMEs employees using COMAU Dual arm robot, offered by the TERRINet partner, The BioRobotics Institute of SSSA, Pisa, Italy.

The Comau Smart Dual arm robot is a robotic system that can be characterized by its many bi-manual tasks that are most often required during main, but also helping processes. Many industrial sectors require specialists for operating automated and robotic workplaces with aim of replacing monotonous and stereotyped repetitive human tasks by powerful advanced dual arms robots. The roles of human moves to more specific and difficulty tasks, where their complex interactions cannot be ever replaced. These innovative bi-manual robotic solutions open new opportunities for human-robot collaboration and bringing together a dream that world dreams about an upcoming new technologies that becomes to be reality.

“Collaborative robots” and their control strategies

Demands and problems for the multi-cobot communication can be accomplished by commonly used methods such is online programming in a following ways. Two control strategies approaches were implemented on UR collaborative robotic system:

- Basic and advanced programming functionalities throughout the cobot teach pendant that are used obviously by programmers and operators to build and execute cobot jobs, such Shirine El Zaatari et al. (2019). Teach pendants offer a variety of settings to control and are also utilized to design new capabilities and features.

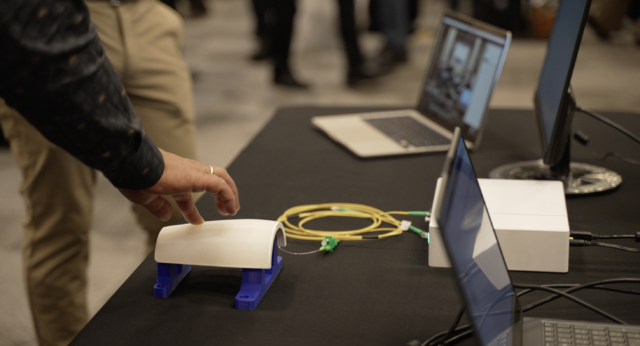

- TCP/IP programming functionalities based communication that allows connection with standard pc as a Server and cobot system as a Client, such Serhat Demirtas et al. (2022). By developing the program software (C++ or python) we are able to control the cobot sending information in a bidirectional way (from the robot to the host pc – i.e. robot ready to listen for the task, and from the host pc to the robot – i.e. pose to reach (Figure 1).

Two-arm robotic systems from COMAU and soft conformable artificial skins

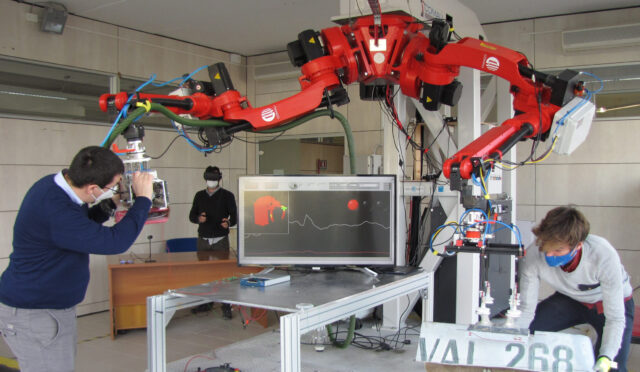

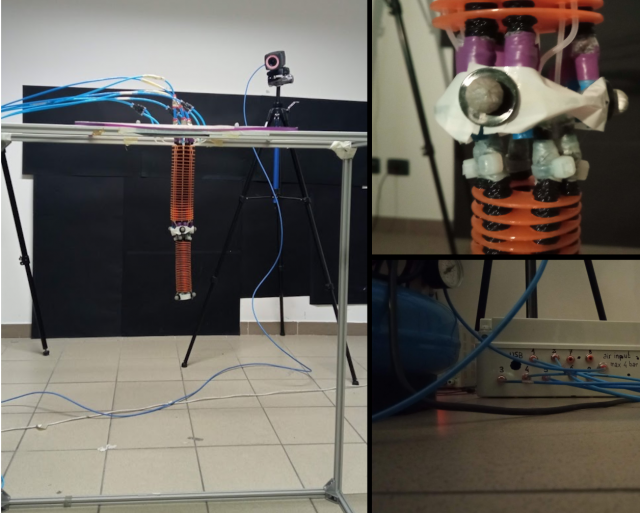

Collaborative robots are expected to physically interact with humans in daily living and workplace, including industrial and healthcare settings. A related key enabling technology is tactile sensing, which currently requires addressing the outstanding scientific challenge to simultaneously detect contact location and intensity by means of soft conformable artificial skins adapting over large areas to the complex curved geometries of robot embodiments (Massari L. et al 2022). In context of this research were collaborative robotic system (COMAU dual arm robotic system that is available at SSSA, Pisa, Italy) tested with the proposed algorithms for post-processing data collection from an accelerometer mounted on this robotic platform to evaluate platform vibrations (Figure 2).

References:

- Shirine El Zaatari, Mohamed Marei, Weidong Li, Zahid Usman, Cobot programming for collaborative industrial tasks: An overview. Robotics and Autonomous Systems, Volume 116, 2019, Pages 162-180, ISSN 0921-8890,https://doi.org/10.1016/j.robot.2019.03.003.

- Serhat Demirtas, Tolga Cankurt, Evren Samur, Development and Implementation of a Collaborative Workspace for Industrial Robots Utilizing a Practical Path Adaptation Algorithm and Augmented Reality, Mechatronics, Volume 84, 2022, 102764, ISSN 0957-4158, https://doi.org/10.1016/j.mechatronics.2022.102764.

- Massari, L., Fransvea, G., D’Abbraccio, J. et al. Functional mimicry of Ruffini receptors with fibre Bragg gratings and deep neural networks enables a bio-inspired large-area tactile-sensitive skin. Nat Mach Intell 4, 425–435 (2022). https://doi.org/10.1038/s42256-022-00487-3